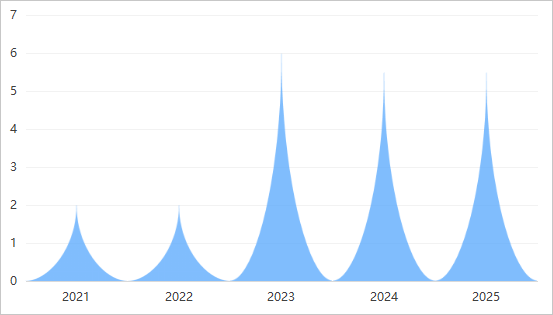

In recent years, nitrile gloves have been widely used in the healthcare industry, manufacturing, laboratory environments, etc. The demand for nitrile gloves is increasing, which is attributed to the excellent properties of nitrile gloves themselves and the continuous enhancement of people’s awareness of health and hygiene. The strict safety regulations in the pharmaceutical, medical, and chemical industries have further promoted the expansion of the nitrile glove market. The COVID-19 pandemic has greatly accelerated global demand, further supporting the long-term development of personal protective equipment (PPE).

Market Forecast Statistics Chart of Nitrile Gloves(2025)

Market Analysis of Nitrile Gloves

Compared with powdered nitrile gloves, powder-free nitrile gloves occupy the largest market segment. The National Medical Products Administration (NMPA) stipulates that powder-free nitrile gloves should be the first choice for medical and food handling, and emphasizes the importance of powder-free gloves in maintaining a sterile environment and preventing latex allergies. Powder-free nitrile gloves can eliminate complications caused by glove powder, such as breathing problems and wound inflammation. This reflects the wide acceptance and support of powder-free gloves in the future market.

Compared with durable thick nitrile gloves, disposable nitrile gloves have occupied a large share of the glove niche market due to their convenience and wide application in medical care, food processing, cleaning, and other fields. The disposable feature of this kind of glove makes it more convenient and hygienic in the operating environment. The COVID-19 pandemic has accelerated the widespread attention paid to the use of nitrile gloves. The requirements for preventing virus transmission and high standards of protection have rapidly increased the demand for nitrile gloves.

Nitrile Gloves Production Process

The raw material of nitrile gloves is nitrile rubber (NBR). Initially, the raw materials are mixed in a stirring system. After the raw materials are ready, the hand molds are washed clean with acidic or alkaline water to ensure there are no chemical residues. Then, immerse the cleaned hand molds in the coagulant (calcium nitrate and calcium carbonate), and then dip them in the prepared nitrile rubber latex mixture. Control the temperature and time well to ensure the thickness of the nitrile gloves. Afterwards, the hand molds with nitrile films are dried in the oven and vulcanized to enhance the physical properties of the gloves and make them more elastic. Afterwards, the hand molds need to be demolded through a glove demolding machine. Finally, the gloves undergo quality tests such as pinhole tests to determine the quality classification of the gloves, and are packaged and stored in the warehouse before shipment.

Nitrile Glove Production Process Flow Chart

Nitrile Gloves Manufacturing Plant Competitive Landscape

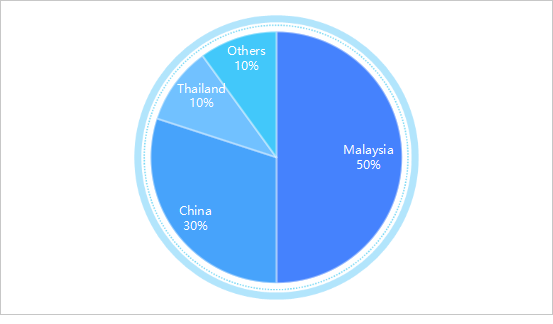

In recent years, the most prominent feature of the global nitrile gloves manufacturing plant has been the changing trend. With the different policies of different countries on trade attitudes between countries, the distribution of the nitrile gloves manufacturing plant is in an extremely unstable state. However, the overall trend remains unchanged. The following chart illustrates the global market share distribution of nitrile gloves. (2025)

Nitrile Gloves’ Global Market Share Percentages(2025)

The Key Questions Answered by Fengwang:

- How do Nitrile Glove Manufacturers Reduce Costs and Increase Efficiency?

- How to Customize Nitrile Glove Production Line?

- How to Buy Metal Glove Formers Cheaper?

- Key Challenges & Solutions in Nitrile Glove Production?

- Fengwang Predicts the Development Trend of Nitrile Gloves?

What Equipment Needed to Establish the Nitrile Gloves Production Plant

- Glove former

- Glove former holder

- Drying oven

- Dipping tank

- Glove former cleaning system

- स्प्रोकेट

- Central glove forming track

- Bearing

- Box spur gear

- Motor

- PLC

- Sterile equipment (optional)

- Intelligent fueling system

- Glove beading machine

- Glove watertight testing machine

- Glove watertight testing machine

- Plastic hand

- Coagulant mixing tank

Our Service

- Model drawing design of nitrile gloves production plant

- Machine transportation and logistics tracking

- Installation and commissioning in the factory area

- Factory latex thread is converted to nitrile thread or nitrile thread to latex thread

- Machine operation instructions, drawings and training

- Optimization of raw material formulas

- Improvement of the production process flow

- Provide relevant machine or production process optimization plans

- On-site after-sales service