Mesin Sarung Tangan Lateks Fengwang

● koagulan surfaktan, pembentukan filem lebih seragam

● Dua barisan pengeluaran: bekas tunggal dan bekas berganda

● Automatik sepenuhnya dan separa automatik mengikut keperluan tersuai

● Sarung tangan yang dihasilkan dipakai dengan lancar dan mengelakkan lekatan

● Kadar kecacatan sarung tangan adalah rendah

● Jika terdapat kerosakan, ia boleh ditutup pada bila-bila masa

Mesin Pembuatan Sarung Tangan Lateks Fengwang

Fengwang ialah pengeluar mesin sarung tangan lateks. Jentera pembuatan sarung tangan lateks semuanya dihasilkan mengikut spesifikasi standard mekanikal antarabangsa dengan sijil lengkap, dan boleh dieksport ke Eropah, Timur Tengah, Asia Tenggara, Amerika Utara, Amerika Selatan dan kawasan lain.

Ia secara automatik mengeluarkan sarung tangan daripada bekas sarung tangan.

Tanggalkan sarung tangan yang terletak di hujung jari, susun untuk mengira.

Sarung tangan dibungkus dalam kotak dan ditutup, mengautomasikan proses penuh.

Digunakan untuk menghilangkan kotoran sisa dari bekas sarung tangan.

Pembinaan biasanya mengambil masa 80-90 hari untuk disiapkan.

Fengwang juga menyediakan latihan proses pengeluaran.

Rakan kongsi Fengwang di China ialah Intco, Bluesail, Hongray dan sebagainya.

Bergantung pada bahan mentah sarung tangan pelanggan ingin membina.

Ciri-ciri Mesin Pembuatan Sarung Tangan Lateks Fengwang

Reka bentuk mengikut keperluan pelanggan dengan model panjang, ketinggian dan kos yang berbeza.

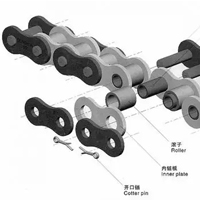

Rantaian berjalan lancar dan pantas kerana seretan kurang.

Filem ini seragam, tanpa pelepasan acuan serbuk.

Berbanding dengan bentuk peredaran udara panas yang lain, menjimatkan penggunaan tenaga hampir 20%.

Gear direka khas untuk mesin membuat sarung tangan lateks, keseluruhan bahagiannya telah dirawat haba, mempunyai rintangan kakisan kimia, dan ketahanan yang tinggi, dan dilengkapi dengan sistem galas beban automatik rantai.

Kadar kelayakan produk mencapai lebih daripada 98%. Kandungan protein lebih rendah daripada 120 mikrogram setiap gram.

Menyelesaikan banyak masalah rumit seperti penyegerakan yang sukar, penyelenggaraan yang kompleks dan banyak lagi kegagalan.

Proses ini boleh mengacau sepenuhnya lateks tanpa fenomena berbuih, dan memenuhi keperluan operasi biasa jangka panjang mesin sarung tangan Lateks.

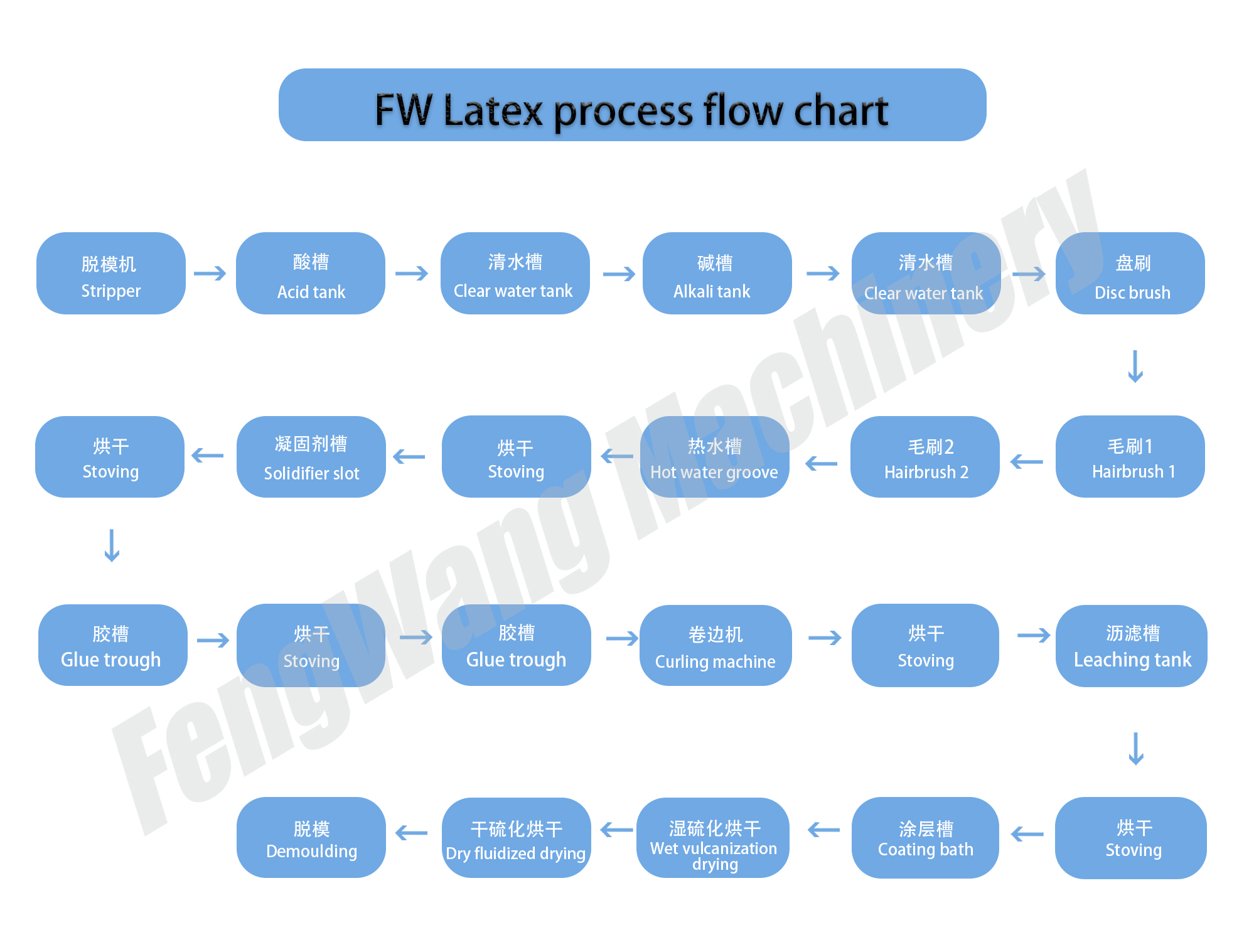

Aliran Proses Barisan Pengeluaran Sarung Tangan Lateks

Fengwang bukan sahaja menyediakan lukisan untuk reka bentuk mesin pembuatan sarung tangan lateks anda, pemasangan, pasca pentauliahan, perkhidmatan penyelenggaraan selepas jualan, tetapi juga menyediakan panduan proses pembuatan sarung tangan lateks, yang merupakan langkah yang sangat penting dalam pembuatan sarung tangan lateks.

Sumber untuk Menyesuaikan Barisan Pengeluaran Sarung Tangan Lateks?

Tiada peralatan standard yang seragam untuk mesin sarung tangan lateks, yang memerlukan pelan perniagaan pembuatan sarung tangan lateks khusus mengikut faktor seperti suhu dan kelembapan di kawasan pengeluaran, kawasan tapak dan output. Dan penyelenggaraan dan peningkatan berterusan barisan pengeluaran sarung tangan lateks.

Adakah Loji Sarung Tangan Lateks Anda Menghadapi Masalah Ini?

- Ingin menyediakan barisan pengeluaran sarung tangan lateks pakai buang, tetapi tidak memahami proses pembuatan sarung tangan lateks dan susun atur barisan?

- Adakah kelajuan barisan pengeluaran tidak setanding?

- Ingin menukar mesin pembuat sarung tangan lateks kepada talian sarung tangan nitril?

- Ingin memperbaiki keadaan semasa mesin pembuatan sarung tangan yang semakin tua?

- Pembentuk sarung tangan tidak boleh dibersihkan?

Talian Pengeluaran Sarung Tangan Lateks Tersuai Fengwang Serius

Fengwang boleh melakukan keseluruhan barisan pengeluaran sarung tangan lateks, juga mesin lateks tunggal dalam barisan pengeluaran, termasuk mesin susun, mesin pelucutan, mesin pembungkusan, mesin manik, bekas sarung tangan, pemegang bekas sarung tangan, mesin mengisi minyak pintar, dll. Fengwang menyediakan anda penyelesaian muktamad apabila anda membangkitkan masalah yang anda hadapi dalam pengeluaran sarung tangan lateks.

Pilih Barisan Pengeluaran Sarung Tangan Lateks Fengwang

Mesin pembuat sarung tangan lateks Fengwang Sejak dua puluh tahun yang lalu, keperluan automasi telah meningkat, dan susun atur bengkel direka mengikut keperluan pelanggan.

Pelanggan akhir mesin pembuatan sarung tangan lateks Fengwang adalah kilang sarung tangan pakai buang di seluruh dunia. Kami memahami keperluan kilang pembuatan sarung tangan dan membuat mesin yang memuaskan hati mereka.

Pelanggan yang telah bekerja dengan kami selama lebih 10 tahun mempercayai kami kerana kami sentiasa menghantar tepat pada masa dengan jaminan kualiti yang boleh dipercayai. Barangan mesti lulus pemeriksaan kualiti yang ketat sebelum mereka meninggalkan kilang. Pelanggan memutuskan sama ada untuk menandatangani barangan selepas penerimaan awal dan akhir.

Fengwang sentiasa dapat menunjukkan kepada pelanggan teknologi terkini dalam industri jentera sarung tangan automatik. Dan boleh menjimatkan kos kilang pembuatan sarung tangan lateks untuk pelanggan mewujudkan kerjasama jangka panjang.

Mengenai Barisan Pengeluaran Sarung Tangan Latex

- Jadual Parameter

|

MODEL TUNGGAL

|

||||

|

MODEL

|

SAIZ MESIN

|

KAPASITI

(pcs/jam) |

Penggunaan haba (10,000 kcal/jam)

|

KUASA(KW)

|

|

FW-RJXS 60

|

60*2.2*9m

|

3,360-4,368

|

40

|

178

|

|

FW-RJXS 80

|

80*2.2*9m

|

7,440-9,672

|

90

|

185

|

|

FW-RJXS 100

|

100*2.2*9m

|

9,480-12,324

|

115

|

210

|

|

FW-RJXS 120

|

120*2.2*9m

|

12,240-15,912

|

150

|

240

|

|

FW-RJXS 140

|

140*2.2*9m

|

14,400-18,720

|

180

|

290

|

|

FW-RJXS 160

|

160*2.2*9m

|

16200-21,060

|

200

|

320

|

|

FW-RJXS 180

|

180*2.2*9m

|

18,600-24,180

|

230

|

360

|

|

MODEL BERGANDA

|

||||

|

MODEL

|

SAIZ MESIN

|

KAPASITI

(pcs/jam) |

Penggunaan haba (10,000 kcal/jam)

|

KUASA(KW)

|

|

FW-RJXD 80

|

80*2.4*12m

|

13,200-17,160

|

160

|

195

|

|

FW-RJXD 100

|

100*2.4*12m

|

18,000-23,400

|

220

|

223

|

|

FW-RJXD 120

|

120*2.4*12m

|

22,800-29,640

|

280

|

250

|

|

FW-RJXD 140

|

140*2.4*12m

|

24,000-31,200

|

290

|

300

|

|

FW-RJXD 160

|

160*2.4*13m

|

31,200-40,560

|

380

|

330

|

|

FW-RJXD 180

|

180*2.4*13m

|

38,400-49,920

|

460

|

380

|

|

FW-RJXD 200

|

200*2.4*13m

|

43,200-56,160

|

520

|

400

|

|

Spesifikasi di atas adalah untuk rujukan, Barisan pengeluaran boleh disesuaikan mengikut keperluan anda.

|

||||

Barisan Pengeluaran Sarung Tangan Lateks

Struktur barisan pengeluaran sarung tangan lateks termasuk berbilang mesin, setiap satu dengan proses khusus untuk memastikan pengeluaran yang cekap, berterusan dan automatik daripada bahan mentah kepada produk siap. Di bawah ialah komponen utama barisan pengeluaran sarung tangan lateks.

Sistem Penyediaan Bahan Mentah. Ia terdiri daripada tangki simpanan lateks, tangki koagulan, peralatan batching dan pencampuran, dan sistem penapisan. Fungsi utamanya adalah untuk menyimpan dan menyediakan bahan mentah lateks dan bahan tambahan kimia lain.

Sistem Pembersihan Acuan dan Pra-rawatan. Terdiri daripada sistem pembersihan bekas sarung tangan, tangki pencelup koagulan dan alat pengering (untuk mengeringkan koagulan). Ia digunakan terutamanya untuk membersihkan acuan dan menggunakan koagulan, menyediakannya untuk proses mencelup lateks seterusnya.

Sistem Pencelupan Lateks. Biasanya termasuk a tangki celup lateks, mekanisme berputar atau dipacu rantai (untuk memastikan acuan acuan yang sama rata), dan peranti kawalan ketebalan lateks. Fungsi utamanya ialah mencelupkan acuan ke dalam lateks untuk membentuk filem sarung tangan yang seragam.

Sistem Pra-pengeringan dan Manik. Terdiri daripada terowong pra-pengeringan dan peranti manik (mekanikal atau pneumatik). Fungsi utamanya adalah untuk mengeringkan terlebih dahulu sarung tangan yang dicelup dan membentuk struktur tepi manik sarung tangan.

Sistem Pemvulkanan. Terdiri daripada ketuhar pemvulkanan dan a sistem kawalan suhu. Fungsi utamanya adalah untuk memaut silang dan menyembuhkan lateks melalui pemvulkanan suhu tinggi, meningkatkan kekuatan dan keanjalan sarung tangan.

Sistem Pencucian dan Pembilasan. Termasuk tangki basuh, tangki bilas, dan sistem peredaran air. Fungsi utamanya adalah untuk membuang sisa bahan kimia dan kekotoran dari permukaan sarung tangan.

Sistem Pengeringan. Terdiri daripada terowong pengeringan dan sistem peredaran udara panas. Fungsi utamanya adalah untuk mengeringkan sarung tangan dengan teliti, memastikan tiada kelembapan kekal dalam produk siap.

Sistem Pelucutan. Terdiri daripada peranti demolding (kuku mekanikal atau peranti pneumatik) dan peranti meniup sarung tangan. Fungsi utamanya adalah untuk mengupas sarung tangan dari acuan.

Sistem Pembungkusan. Termasuk an peranti pengiraan automatik, mesin pembungkusan dan mesin pelabelan. Fungsi utamanya adalah untuk membungkus sarung tangan yang layak dalam kuantiti tertentu.

Sistem Kawalan. Terdiri daripada PLC (Programmable Logic Controller), HMI (Human-Machine Interface), sensor dan sistem maklum balas. Fungsi utamanya adalah untuk memantau dan mengawal selia operasi keseluruhan barisan pengeluaran.

Peralatan Bantu. Termasuk sistem udara termampat, sistem rawatan air, dan sistem rawatan gas ekzos (untuk memenuhi keperluan alam sekitar). Fungsi utamanya adalah untuk menyokong operasi normal barisan pengeluaran.

Secara ringkasnya, barisan pembuatan sarung tangan lateks ialah sistem pengeluaran pintar yang sangat bersepadu yang melibatkan keseluruhan proses daripada pengendalian bahan mentah kepada pembungkusan produk siap. Dengan pengalaman bertahun-tahun dan peningkatan teknologi, garisan sarung tangan lateks Fengwang Tech terkenal dengan kecekapan, kepintaran dan automasi penuhnya, menjadikannya sangat popular di kalangan pengeluar sarung tangan.