Fengwang Promote Your Business

- Nitrile gloves manufacturing machines are divided into single-mold and double-mold types. The type of glove production line is ultimately determined based on your production volume requirements.

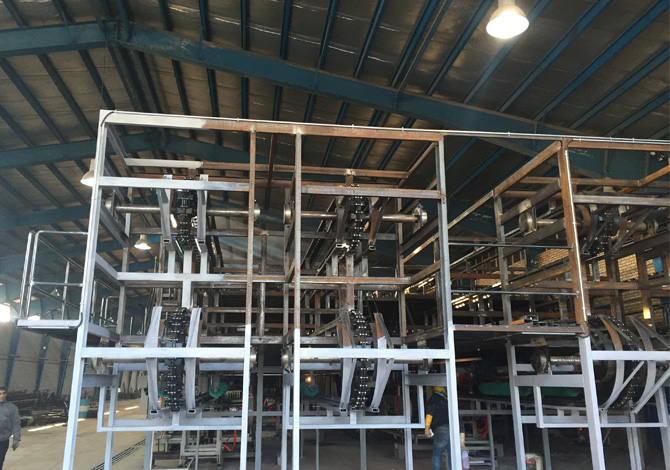

- The structure of the entire production line is made of steel to enhance the overall durability and firmness.

- The machine parameters of each part of the nitrile glove production process can be adjusted with one click for convenient operation.

Nitrile Glove Machine for Sale

Fengwang offers high-quality design and installation of nitrile glove production lines. As a leading manufacturer of advanced nitrile glove manufacturing machines in China, we place great importance on mechanical quality and after-sales service, strictly adhering to contract standards and national mechanical manufacturing industry norms. This has made our reputation and product quality far exceed those of our peers.

The nitrile glove production line is a complete, modern, intelligent production system. Each production process needs to be precisely controlled. The professional R&D team and advanced technology inject impetus into the development of Fengwang.

Your Nitrile Glove Production Line Manufacturer

Production Processes for Nitrile Glove Production Lines

Nitrile Gloves Machinery Debugging

After the Nitrile glove machine is installed, it enters the commissioning stage, which includes the commissioning of environmental temperature and humidity, machine parameters, chemical reagent ratio, production line speed, impregnation time, etc. By continuously optimizing the nitrile glove production process, reducing the manufacturing plant cost of nitrile gloves, and enhancing the production efficiency of nitrile gloves.

About Quality Inspection

Product quality is an important indicator of an enterprise’s success or failure.

Fengwang is equipped with advanced testing equipment and has rich testing experience. A quality inspection department has been established to ensure the stable operation of machine parts and components. We accurately identify and solve problems with professional testing items to guarantee the quality of our products.

Why 1000+ Customers Choose Fengwang?

Fengwang provides one-stop service.Customers can provide site information or even an idea, we can specially design, manufacture and install for customers. After installation, we will train the customer on the machine operation process until they can fully master the production process.

20 years of experience in foreign trade enables in-depth understanding of customer needs. Constantly update the latest ideas of machine manufacturing to meet the latest ideas of customers on machines. Fengwang has always been at the forefront of technology in the nitrile gloves machinery.

Our factory is a large modern workshop, which is equipped with a wide range of modern machining equipment and loading equipment to prevent the machine from being worn out in transit.All in the interests of customers.

Fengwang thanks customers who are enthusiastic about the machine and support customers to visit our factory. At present, our customers come from Iran, Turkey, Ethiopia, Malaysia, Vietnam, Algeria and so on. We like to make friends with people from more countries.

About Nitrile Gloves Production Line

- Parameter Table

|

SINGLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWSM60

|

60*2.2*9m

|

3,360-4,368

|

40

|

178

|

|

FWSM80

|

80*2.2*9m

|

7,440-9,672

|

90

|

185

|

|

FWSM100

|

100*2.2*9m

|

9,480-12,324

|

115

|

210

|

|

FWSM120

|

120*2.2*9m

|

12,240-15,912

|

150

|

240

|

|

FWSM140

|

140*2.2*9m

|

14,400-18,720

|

180

|

290

|

|

FWSM160

|

160*2.2*9m

|

16200-21,060

|

200

|

320

|

|

FWSM180

|

180*2.2*9m

|

18,600-24,180

|

230

|

360

|

|

DOUBLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWDM80

|

80*2.4*12m

|

13,200-17,160

|

160

|

195

|

|

FWDM100

|

100*2.4*12m

|

18,000-23,400

|

220

|

223

|

|

FWDM120

|

120*2.4*12m

|

22,800-29,640

|

280

|

250

|

|

FWDM140

|

140*2.4*12m

|

24,000-31,200

|

290

|

300

|

|

FWDM160

|

160*2.4*13m

|

31,200-40,560

|

380

|

330

|

|

FWDM180

|

180*2.4*13m

|

38,400-49,920

|

460

|

380

|

|

FWDM200

|

200*2.4*13m

|

43,200-56,160

|

520

|

400

|

|

The above specifications are for reference,Production lines can be customized according to your requirements.

|

||||

You should prepare workshop, water lines, electrical wiring, compressed air (if you need, we can help you buy an air compressor). We can provide workshop layout drawings according to your workshop.

The lead time for a production line is about 90 days. (According to the actual order situation)

Customers can choose to pay in installments, we accept T/T, platform direct payment, etc.

China (Bluesail, Intco, Zhonghong, Hongray, Wanli), Malaysia, Turkey, Vietnam, South Korea, Southeast Asia and other countries.

Choose the product you like, or send us your requirements, and our engineers can create a project and quote for you. (Then, confirm all details and sign the contract. You can make an advance payment, and we will start purchasing raw materials for production. The product will be shipped according to our agreement. )

Of course, we are located in Shijiazhuang, China, you can take a plane to Shanghai, then take a high-speed train or plane to Shijiazhuang, we will arrange a driver to pick you up. Welcome to visit our factory.

We will provide installation drawings and videos. We can also send professional technicians to your company to guide the installation of the machine and train your staff on-site until they can operate the machine independently.

We need to know how much production space, how much production capacity, the need for new production lines or modifications, a certain machine, or just maintenance, and so on?

For our customers, our machines are very durable and have a 1-year warranty. Some machines provide remote program upgrade services. Also, after-sales services includemaintenance,on-site training, and more.

From designing,debugging to delivery, we will send related pictures and videos for customers to track the production process. We will also update you when our engineers complete the development of special requirements.

We still offer our repair services to you even when the warranty time is over. This service does not have an expiry date.

If you encounter any problem with nitrile gloves manufacturing machine, we can offer:

User manual in English

Operation video

24/7 online support

You can also send your technician to nitrile gloves making machine manufacturers to attend the skills training to operate and maintain your new nitrile glove machine.

Nitrile Glove Manufacturing Equipment Application

In recent years, the global demand for nitrile gloves has been increasing continuously, mainly manifested in the following fields

The medical field

Nitrile gloves are widely used in the medical field because their material is not allergic to the skin, they are in close contact with the skin for easy, precise operations, and they have excellent chemical resistance etc.

Food processing

Due to the increasing emphasis on food hygiene in recent years and the strict requirements of food hygiene inspection departments, the demand for nitrile gloves is also constantly increasing to ensure food hygiene.

The field of electronics industry

Nitrile gloves are resistant to oil, heat, and chemical corrosion, which makes them widely used in the maintenance and manufacturing of electronic equipment, chemical industry, glass, aquaculture, and other fields. They are excellent hand protection equipment.

Transportation And Packaging

The packaging of Fengwang is made of high-strength and wear-resistant wood to resist the collision and friction of nitrile gloves machinery during transportation. Inside the wooden box, meticulous reinforcement treatment was also carried out, such as using steel strips, wooden strips, and other materials for reinforcement.

The filling of plastic film or other sealing materials ensures that the equipment remains dry in a humid environment. Wrap all the equipment with several layers of cling film and then another layer of bubble wrap for shock absorption and vibration reduction.

The packaging is marked with the equipment name, model, quantity, weight, destination, and other information, which is convenient for quick identification and management during transportation and handling. Implement Internet of Things (IoT) technology for core components to monitor, track, and track the delivery and operation status of spare parts in real time and dynamically.

About Delivery Date

The delivery time of Fengwang is divided into standard delivery time and special delivery time.

Standard delivery period: It refers to the period calculated from the date of receiving the full payment or signing the contract.

Special delivery time: For customized large-scale equipment, the delivery time will be adjusted according to the actual situation. We will negotiate with you to determine the delivery date based on the specific circumstances of the project, and the delivery period will be confirmed in the contract after mutual agreement.

For the delivery dates of different spare parts and consumables of the equipment under different usage environments, we will jointly formulate spare parts plans with customers and deliver them as needed.

On Machine Safety Usage

The Fengwang Auto nitrile glove production machine includes various transmission devices, power devices, and load equipment. To ensure the safety of the operators and the normal operation of the equipment, Fengwang has taken the following safety protection measures:

1. Install the one-click shutdown button. Beside each production process machine, there is a one-click shutdown button. In case of emergency failure, it is convenient to stop the machine with one click to reduce losses.

2. Install the alarm device. This device is installed to trigger an alarm when the machine malfunctions or when people approach certain unsafe areas, thereby reducing unnecessary losses.

3. Install leakage protection devices. Fengwang installs leakage protection devices that comply with national standards to prevent personal injury caused by leakage.

Our Service

- Model drawing design of nitrile gloves production plant

- Machine transportation and logistics tracking

- Installation and commissioning in the factory area

- Factory latex line is converted to nitrile line, or nitrile line to latex line

- Machine operation instructions, drawings, and training

- Improvement of the production process flow

- On-site after-sales service