The Importance of Glove Former Cleaning Process

Environmental hygiene is paramount in producing gloves using industrial glove former, medical glove former, surgical glove former, inspection glove former, etc. The production of high-quality gloves requires pollution-free hand forms for gloves. Otherwise, the accumulated residue will cause wear, corrosion, or other damage to the glove former, resulting in frequent replacement of the glove former and increasing the cost of the glove manufacturer.

Therefore, it is very important to master the glove former cleaning process, which can extend the service life of the glove former, reduce the frequency of maintenance or replacement, and improve the overall production efficiency.

Types of Glove Former

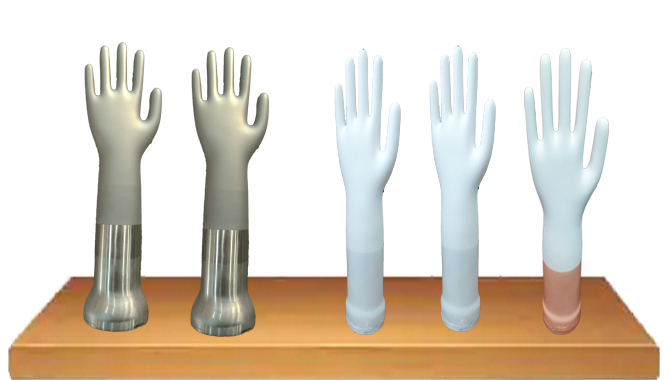

In the production process of nitrile latex PVC gloves, hand forms for gloves are used for glove molding, they have size points, and there are also differences in material. Quality hand forms for gloves will save glove makers a lot of trouble, so what are the Types of glove former?

Classification by size: Usually hand forms for gloves will be divided into XS, S, M, L, XL, and XXL.

Classification by material: Hand forms for gloves are divided into iron, ceramic, plastic, and aluminum.

Hand Model Cleaning Machine Video

The video on the left is the glove former cleaning machine that Fengwang just produced for the customer. Li Jianqiang, leader of Fengwang Company, personally introduced the assembly principle, material, and related contents of this machine.

Glove Former Cleaning Process

The glove mold hand must be cleaned before being immersed in the raw material. Uncleaned gloves participating in the glove manufacturing process can cause the following problems:

1. Microbial contamination occurs in the gloves produced.

2. Gloves are incomplete and have holes or dirt.

Brush cleans the glove former video

Fengwang Technology engineers say that the cleaning process of the glove model usually involves the following steps:

Pickling: The glove mold hand is immersed in the pickling solution. After pickling, rinse the glove mold hand with clean water. At this point, the model is dipped in an alkaline solution to neutralize the remaining acid on the hand model. After rinsing the mold with clean water, scrub the glove mold hand to ensure that it is completely clean without stains. The cleanliness of the hand model is an important prerequisite to ensuring the production of high-quality gloves.

Fengwang Glove Former Cleaning Machine

Glove former cleaning machine video

- Glove former cleaning machine structure

The glove former cleaning machine is a fully automatic glove former cleaning system. Under normal circumstances, the glove former cleaning system comprises a pickling tank, an alkali washing tank, a cleaning mold disk brush and cross brush, and two heating sinks.

- Glove former cleaning machine material

Fengwang manufacturing these gloves production equipment is made of high quality materials. Among them, the function of the disk brush and the horizontal brush is to clean the stains on the hand model, and they are required to clean the stains on the hand model accurately without damaging it.

Therefore, the disk brush and horizontal brush are usually made of engineering plastic plates and nylon plates. The horizontal brush is used to clean the glove former’s palms and fingers, and the disc brush is used to clean the glove former’s wrists and above.

The heating tank is a single-layer direct heating tank made of 3mm sus304 stainless steel. In general, the capacity of each tank is manufactured according to the process requirements.

- Glove former cleaning machine cleaning process

Each slot function of the automatic glove former cleaning system is different. The glove former is immersed in the pickling tank to clean the residue on the mold, and the glove former is passed through the alkaline cleaning tank to clean and neutralize the acidic water on the mold. After that, the glove former went into the washing and cleaning mode to ensure the initial cleaning effect of the mold. Finally, the glove former went through two hot sinks to wash the dust on the mold, so that the glove former was completely cleaned.

- Heating water tank design

The heating sink is made of SUS304 stainless steel pipe as a heating coil, the coil is directly placed at the bottom of the tank of the heating sink, and the cleaning liquid is heated by the way of wall heat dissipation to achieve the best constant temperature effect.

The above is the cleaning process of the glove former cleaning machine. A high-quality Inspection gloves production requires a clean glove manufacturing plant and non-contaminated hand molds. So you may need a glove former cleaning system now, please contact us immediately.

Various Functions of the Brush in the Glove Production Line

Brushes are an important tool in glove production lines because they remove debris and contaminants without damaging the glove mold. Here are some brush types used in the glove manufacturing process:

Large disk brush

These brushes have long, flexible bristles that clean between the fingers of hand formers.

Beading and cuff brush

These brushes can be used to create curly edges on gloves and cuffs. The bristles must be flexible enough to make curly edges without damaging the hand glove mold.

Glove stripping brush

These brushes are used to remove gloves from the hand glove mold after the latex has dried. They usually are nylon or PBT bristles.

Rotate round brush or roll brush

These brushes are used to pull gloves out of the mold after dipping, coating, and drying.

Fengwang-Your Premium Glove Production Line Manufacturer

Fengwang Technology Co., LTD., founded in 1999, is a one-stop solution enterprise integrating development, design, manufacturing, installation, and commissioning. For more than 20 years, Fengwang has been committed to the production of nitrile latex PVC glove production line, surgical glove production line, household glove production line and glove stripping machine, glove counting machine, glove packaging machine spare parts.

Now our company covers an area of more than 20,000 square meters, has more than 70 employees, several processing and manufacturing bases, and has cooperated with several large machinery manufacturing enterprises to create a one-stop technical service platform for disposable glove production line equipment. Our company specializes in the design and manufacture of nitrile, latex, and PVC gloves production lines and spare parts.

Automatic glove making equipment fully meets the industry’s various product development needs, dedicated to providing enterprises with a full range of technical consulting, equipment transformation, and upgrading services.

Why Choose Fengwang

- Provide the most advanced production technology, process, and formula in China, and have overseas companies as partners.

- More than 20 years of experience in international project contracting, providing one-stop turnkey projects and perfect after-sales service.

- China’s largest glove manufacturing machine production and processing base, with sufficient production, processing, and manufacturing capacity.

- Located near the port of Tianjin, the company has the natural conditions to cooperate with overseas glove manufacturers, facilitate exports, and has skilled international business capabilities.