Nitrile Glove Material

Nitrile gloves are made of nitrile rubber, which is a synthetic elastomer. Due to the special material of nitrile gloves, nitrile gloves have the following properties: high temperature resistance, good water resistance, resistance to chemicals, and so on.

What Colors are Available in Nitrile Gloves

The most commonly used colors of nitrile gloves are white, black, blue, purple, orange, and other colors used in different areas of life and production.

Blue nitrile gloves are used in medical hygiene and daily cleaning, white nitrile gloves are used in electronic instrument processing and manufacturing, and black nitrile gloves are used in the field of food and beauty salons.

In general, there is no difference between different colors of gloves, the choice of what color of gloves can be based on their preferences and personal needs, but it should be noted that the quality requirements of gloves in different areas may not be the same, need to be careful to buy.

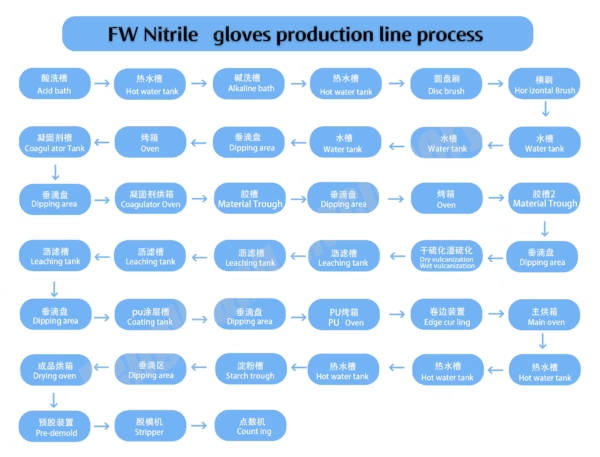

Fengwang Nitrile Glove Production Process

In general, the production process of nitrile gloves is more complex, and each link needs to be strictly monitored and controlled, the parameters of the machine are adjusted to the best position, energy saving, and environmental protection, but also improve the production efficiency of nitrile glove manufacturers. The following is the production process of Fengwang nitrile gloves.

The nitrile latex, the raw material of nitrile gloves, is mixed with some chemical additives to form a nitrile glove impregnation solution. The glove former on the production line needs to be cleaned before being immersed in the impregnating solution. The glove former cleaning machine specially designed by Fengwang can completely clean the stains and chemical substances on the glove former. The glove former is then placed in the oven to dry.

After drying, the hand model needs to be immersed in coagulant and dried again to form a uniform coagulant film on the surface of the glove former, which helps the adhesion of the nitrile impregnation solution.

The glove former is now ready to dip into the original nitrile dip. After the nitrile hand mold with nitrile dip is dried, the next process is leaching, which is to remove impurities from the surface of the glove, and then the glove former needs to pass through the glove beading machine for cuff crimping.

The gloves then need to be vulcanized, which is to improve the physical properties and chemical stability of the gloves. Gloves need to be cleaned and unmoulded. Fengwang’s automatic glove stripping machine guarantees excellent stripping results and is well received by glove manufacturers.

The Development Trend of Nitrile Gloves

Glove manufacturers said that: the nitrile glove industry market scale is expanding, according to the latest China Market Research Center data, China’s rubber glove market is in the late stage of growth, and the market has a clear expansion trend. The development trend of the nitrile glove market will continue to rise.

For a long time, Malaysia has occupied the main market of nitrile gloves, and the economic scale is stable. Although the introduction of the nitrile glove production line in China is relatively late, China’s industrial facilities, manufacturing costs, etc. are much superior to Malaysia, so the nitrile gloves made in China have more competitive advantages compared to other countries, and the quality and price are more acceptable.

Because the customer’s choice of nitrile gloves itself means that the quality and use of the environment have higher requirements, therefore, the low-end nitrile gloves market and living space is shrinking, its production and sales are gradually concentrated in the high-end products, the product quality requirements are getting higher and higher.

At the same time, because the input cost of nitrile glove production line is higher than that of PVC gloves, there are fewer professionals, and the capital and technical threshold of nitrile glove industry is higher. However, with the very stable and rapid development of China’s industry, as well as the arrival of Industry 4.0 intelligent manufacturing, laws and regulations such as labor law have gradually strengthened the protection of workers, and the investment of enterprises in labor insurance products has also increased significantly. Nitrile gloves become a priority for enterprises when choosing gloves; China has become a major global consumer of NBR, with the demand for gloves growing by more than 10% per year. Therefore, whether at home or abroad, Nitrile gloves have great potential in the future market.